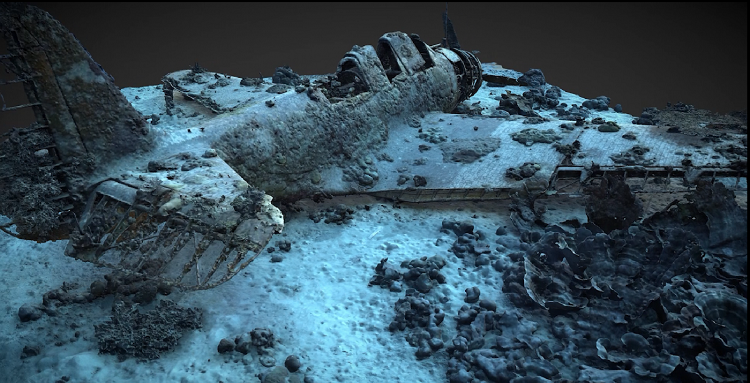

Credit: 3D at Depth_x000D_

Credit: 3D at Depth_x000D_

By MarEx 2019-04-08 19:08:21

_x000D_

Subsea imaging company 3D at Depth has used new laser technology to create a 3D reverse engineered model of the wreck of an historical U.S. Navy plane.

_x000D_

The company used an underwater survey technique that integrates photogrammetry with Subsea laser LiDAR technology on the U.S. Navy Douglas TBD-1 Devastator aircraft that is largely intact on the bottom of Jaluit Lagoon in the Marshall Islands. Of the 129 Devastators built, all were either lost in battle, destroyed in operational accidents or scrapped before the end of World War II.

_x000D_

_x000D_

The new modelling technique was developed during an October 2018 expedition with the nonprofit Air/Sea Heritage Foundation to document the wreck. Part of the ongoing Devastator Project, the expedition was developed to capture precise, repeatable, millimetric data to build an accurate 3D model to serve as a pre-disturbance survey for the proposed recovery of the plane for the National Museum of the United States Navy in Washington, DC.

_x000D_

This particular plane, U.S. Navy Bureau of Aeronautics Number (BuNo) 1515, formerly assigned to Torpedo Squadron Five (VT-5) aboard the aircraft carrier USS Yorktown (CV-5) is located in a sensitive marine habitat. Although Devastator 1515 appeared largely intact from previous research expeditions, the sensitive nature of the wreck and often low water clarity conditions around the site provided limitations for most of the standard data collection processes and other optical imagery collection methods.

_x000D_

Over a period of six days on site, dozens of dives were conducted to the wreck located under 130 feet of water. 3D at Depth’s SL3 laser was deployed at varying ranges from the wreck site. The SL3 pulsed at 40,000 measurements/sec for each scan position acquiring very high-density sector scans. 3D at Depth’s patented index of refraction correction algorithm was able to deliver repeatable data sets in low clarity water quality where other optical solutions would struggle to operate.

_x000D_

In total, the SL3 LiDAR laser delivered a total of 92 million points and the photogrammetric data after processing produced 5.7 million vertices. Each dense point cloud was then surface modeled and moved into a 3D design computer. Optical imagery from photogrammetry, 360 VR and stills were integrated into the designs to render an exact 3D model of the Devastator. Along with the laser LiDAR data, the team captured 1,398 still images with photogrammetry.

_x000D_

source: www.maritime-executive.com

_x000D_

_x000D_